In Legazpi we are unwavering when it comes to the quality of our precision machining work, both on simple parts and on those involving complex geometries. That’s why, as well as having a qualified team of professionals with extensive experience in the machining of parts, it is essential to have equipment at the cutting-edge of technology.

WE HAVE 3 BUILDINGS WITH A SURFACE AREA OF MORE THAN 1.000 M², ONE OF WHICH HAS AIR CONDITIONING TO KEEP IT AT A CONSTANT TEMPERATURE.

We always work with means of production by the leading brands such as DMG Mori or Deckel Maho, guaranteeing quality results and a versatility that’s fundamental when it comes to machining parts for myriad sectors. As well as our universal machining centres, milling machines and other auxiliary elements such as 3 bridge cranes for up to 6 Tn and a jib crane of 1 Tn, at Mecanizados Legazpi we have two centres equipped with U (6-axis) CNC machining.

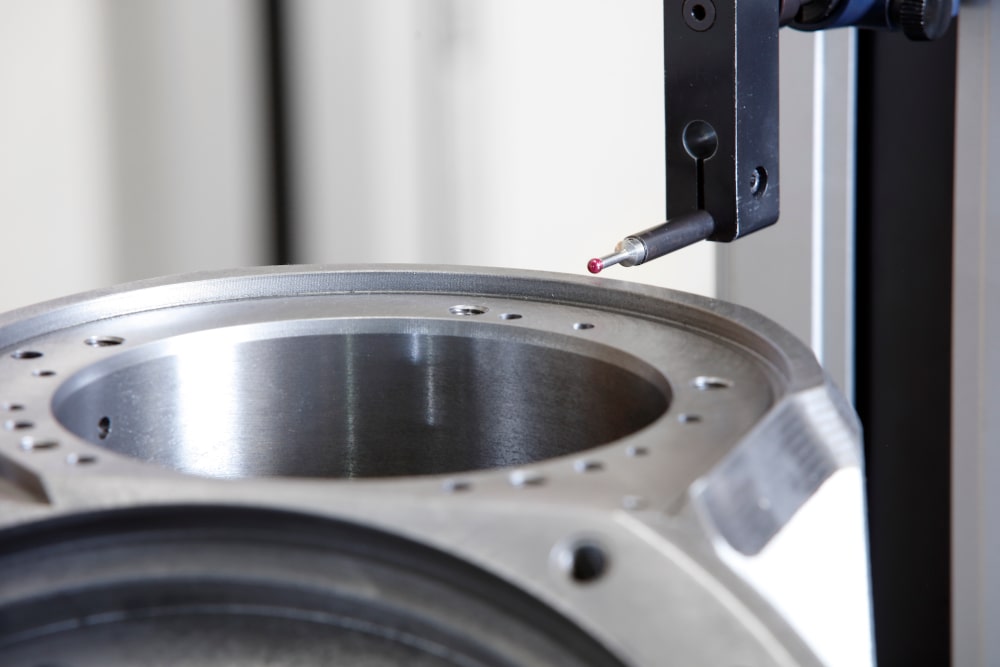

Thanks to our two U-axis machining centres, we can undertake demanding work involving conical bores and interior and exterior diameters with complex geometries. Our U-axis machining centres mean that we can achieve conical bores with conicity errors of less than 0.005 mm over a length of 200 mm, with ovaling deformations of less than 0.003 mm for diameters of 200 mm and roughnesses of Ra 0.8. These possibilities make us highly competitive for certain types of machining involving static parts.

The precision and quality of the machining results are possible thanks to the CNC palpation and digitalization (Heidenhain) system featuring on our machining centres. These dimensional and geometric measurements are taken throughout the machining process, thereby compensating for the errors generated by tensions in the part or thermal stability errors in the machine.

+34 943 73 16 16

+34 943 73 16 16

+34 943 73 16 16

+34 943 73 16 16

?

?